In today’s food processing industry, achieving operational efficiency and maximizing earnings depend on managing key factors like product giveaways and overproduction. With raw food accounting for approximately 75% of manufacturing costs—compared to just 25% for administration— minimizing waste can lead to significant savings. But what exactly does product “giveaway” mean, how much can be saved, and how can businesses capitalize on this opportunity?

What Is Giveaway?

The term “giveaway” refers to the extra product included in a package beyond the labeled weight or volume. For instance, if a package is labeled to contain 500 grams but actually contains 525 grams, those additional 25 grams constitute the giveaway. While this might seem like a small difference, over time and large production volumes, it translates to significant losses in potential revenue.

Let’s take a closer look at how this affects your bottom line. If you’re selling products at a fixed weight basis and the package consistently contains more than promised, your company is effectively giving away extra product for free, reducing overall profitability.

Why Focus on Reducing Giveaways?

Reducing giveaways can lead to significant cost savings, improved operational efficiency, and enhanced profitability. Here are some key ways to achieve this:

- Automated and Advanced Batching Equipment. Precision batching systems ensure accurate measurements during production, reducing overproduction and minimizing giveaways.

- Automated Check Weighing Devices. These systems continuously monitor the weight of packages, allowing for real-time adjustments to maintain accuracy.

- Packing and Labeling Solutions. Both manual and automated systems can streamline processes and improve consistency in packaging.

- Software Solutions. Implementing software to monitor and manage packing operations provides actionable insights and enables tighter control over production processes.

How to Calculate Giveaways

Understanding your giveaways begins with measurement. Below are examples of how giveaways are calculated across different food processing sectors:

Industry | Labeled Weight/Volume | Actual Weight/Volume | Giveaway Weight | Giveaway Percentage |

Meat Processing | 500 grams | 525 grams | 25 grams | 5% |

Dairy Processing | 1 liter | 1.05 liters | 0.05 liters | 5% |

Snack Food Processing | 200 grams | 210 grams | 10 grams | 5% |

These examples show how even small differences can add up, significantly affecting costs over time. For instance, just 10 grams of overweight can result in a 5% giveaway.

Now, let’s take a look at how much you could lose annually with a 5% giveaway and how reducing it by 3% could lead to significant cost savings.

A Business Case Study

Let’s consider a hypothetical scenario to demonstrate the potential savings:

Scenario:

- Daily Production: 10 tonnes of product A

- Production Days: 250 annually

- Sales Price: €1.50 per kilogram

- Current Giveaway: 5%

Calculation:

Category | Weight | Percentage | € |

Annual Production of Product A | 2,500,000 kg | ||

Average Sales Price | 1.50 €/kg | ||

Current Giveaway | 125,000 kg | 5% | 187,500 € |

Reduced Giveaway | 50,000 kg | 2% | 75,000 € |

Profit Gain | 112,500 € |

In this case study reducing the giveaway by just 3% saved a company over €112,000 annually. While the numbers are hypothetical, they are realistic and reflective of actual industry scenarios.

Other examples

Dairy products manufacturing example

Imagine a dairy company producing yogurt in 1-liter bottles. By using advanced check weighing devices and monitoring software, they notice a consistent 0.05-liter overfill in each bottle. Over a year, this small overfill results in a substantial loss. With optimized equipment and monitoring, they bring the overfill down to 0.01 liters, saving thousands of euros annually.

Snack Food manufacturing example

Or consider a snack food manufacturer that reduces its giveaway percentage from 5% to 3% by implementing precision packaging technology. Over time, the financial and resource savings dramatically improve the company’s profitabilit

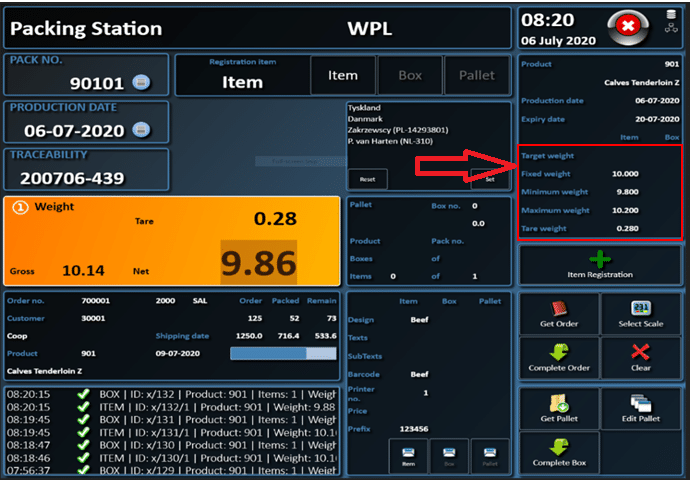

ScanPlant Solution

Here is an example of a Scanplant NG packing station allow to weight various type of products, and managing the give aways through upper and lower limits on the product being weighed and labelled (see in the photo inside the red square).

Later with this control it is possible to move the products, which are outside the weight range, to the reject and make the production and business decisions better.

Ready to Unlock Your Potential?

As we’ve seen, reducing giveaways isn’t just about cutting costs—it’s about optimizing operations and maximizing profitability. With the right tools and strategies, businesses can achieve significant savings while maintaining product quality and customer satisfaction.

Want to learn better how to minimize giveaways and streamline your production? Join our free online webinar:

📌 Topic: Digitalization in Manufacturing- How to Optimize Production and Reduce Product Giveaways

📅 Date: February 28

⏰ Time: 10:00 (EET)

In this webinar, we’ll dive deeper into real case studies and practical methods to improve processes and reduce giveaways in manufacturing, with a special focus on dairy product processing.

👉 Register here: Webinar Link