The pocket-type fish nobbing and filleting machine has been acknowledged in the industry yet ever improving in order to advance machine performance, increase production line productivity and to outstand within the industry.

The cutting-edge technologies implemented for nobbing machine improvements are feeding unit, laser measurement system and Vision System for fish Belly orientation. All these technologies combined in the Pocket-type fish nobbing and filleting machine provide significantly higher yield and cost efficiency.

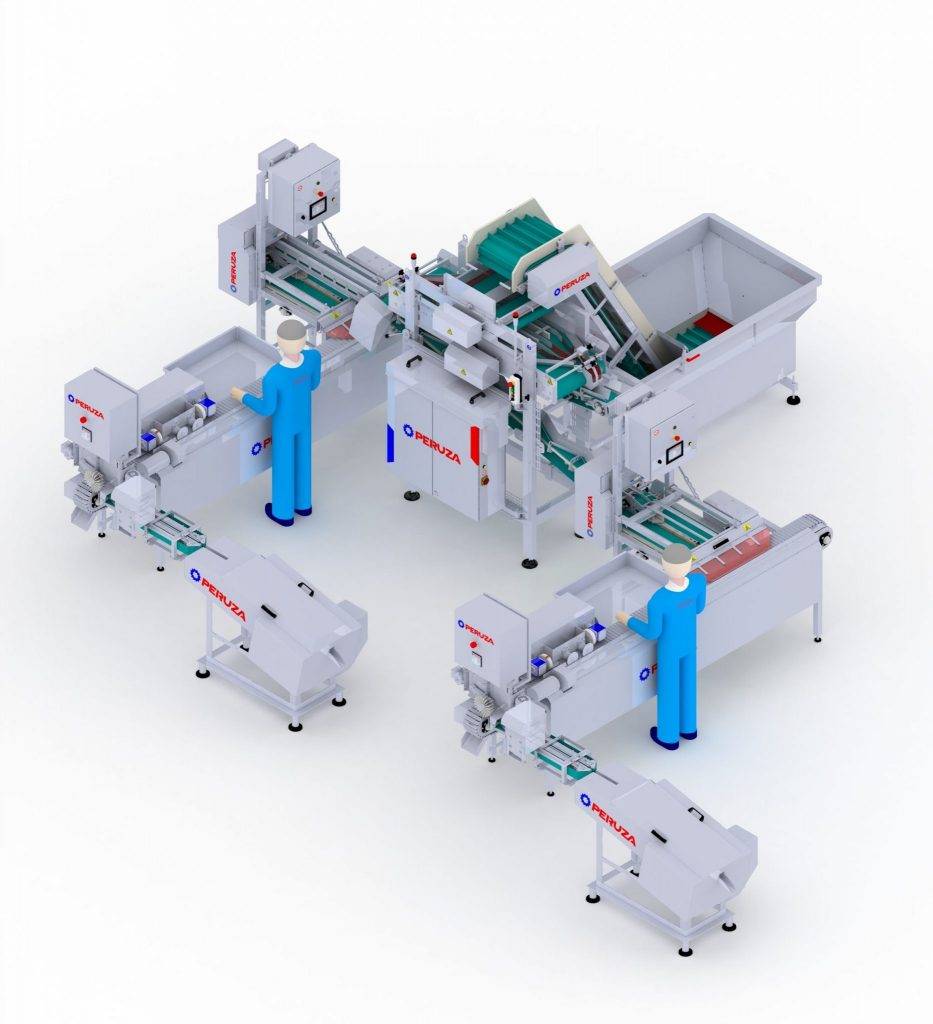

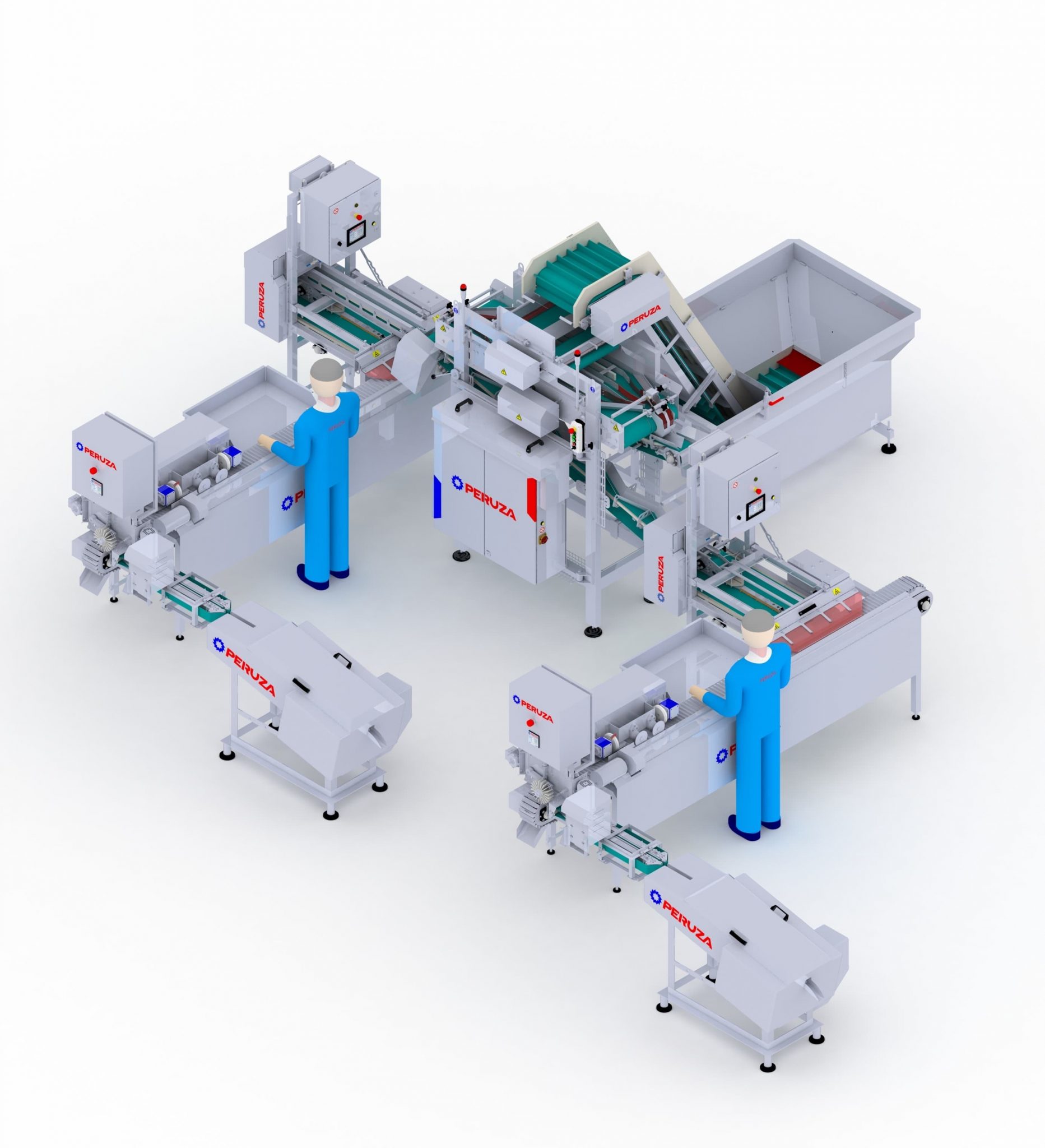

Pocket-type fish nobbing and filleting machine is offered to be combined with other modules. The most extensive system includes PERUZA Autofeeder, PERUZA nobbing machine, Vision System for Belly orientation and PERUZA filleting module.

PERUZA Autofeeder, nobbing machine and filleting module

Up to 400 fillets are prepared within a minute and only two operators involved, thanks to the extensive module system that is the most compact nobbing system in the market.

How does it work?

When using PERUZA Autofeeder, the raw product input is made as easy as possible. Pelagic fish such as sardines, mackerel, herring, anchovy (other species are approved on case by case studies) are introduced into the PERUZA Autofeeder hopper tank. Later fish gets separated and oriented in order to be placed within the pockets separately. Only one operator is needed by each PERUZA nobbing machine to monitor the quality and process. Thus the raw products of lower quality can be eliminated from the production process at early stage.

All fishes entered in the pockets approach the knives for beheading and detailing yet beforehand every fish is being measured separately by the use of electric signals in order to make digital and most precise measurements for cutting. The automatic measuring provide more precise measurements for cutting, thus increasing the yield significantly.

Latest improvement implemented in the system is the special chain technology that allows to comply with higher hygiene standards and reduces system wear and noise. This unique chain technology makes PERUZA nobbing machine the most robust and reliable in the market.

Further fish gets to the vacuum-gutting – by far the most effective and cleanest gutting method used specifically in the PERUZA Pocket-type fish nobbing and filleting machine. As an option, machine can be equipped with mechanical gutting system as well.

Other benefits of the PERUZA Pocket-type fish nobbing and filleting machine is the equipment size and water saving feature. The machine is the most compact in the market – machine takes only 8350 x 6350 mm of floorspace! Beyond the compact design many features are implemented. The water saving feature allows fish to move within the system by providing water jets only when fish is approaching the sensor.

In order to further advance nobbing and filleting operations, We are proud to introduce our innovation the Vision System for Belly orientation. This system makes further production steps more efficient by visually recognising belly orientation of every fish and turning it in needed direction. Our system ensures that no fish is processed more than once in the system and no repeated cycles are needed, while competitors use mechanical belly orientation thus sending a fish through same processes many times before next production steps in case of wrong belly orientation.

When using Vision System for Belly orientation each fish is scanned and prepared properly for the next production step – in such way reducing the quality and efficiency loss.

For more information about the PERUZA module system, separate modules, benefits on using the PERUZA Pocket-type fish nobbing and filleting machine or other inquiries, please contact our Sales Managers by e-mail guntis@peruza.lv!