If you manage a food manufacturing company that works with fish processing or meat packing, you most probably know the struggle of working with multiple suppliers – you can never be sure that they will get the product to you on time or no major errors will occur.

And sure – you can’t always make everything perfect because a lot of times unexpected slipups may happen but you can most definitely reduce the risk of them happening.

So now is the right time to look for food manufacturing solutions that suit your business needs and goals the best.

What are the best options out there?

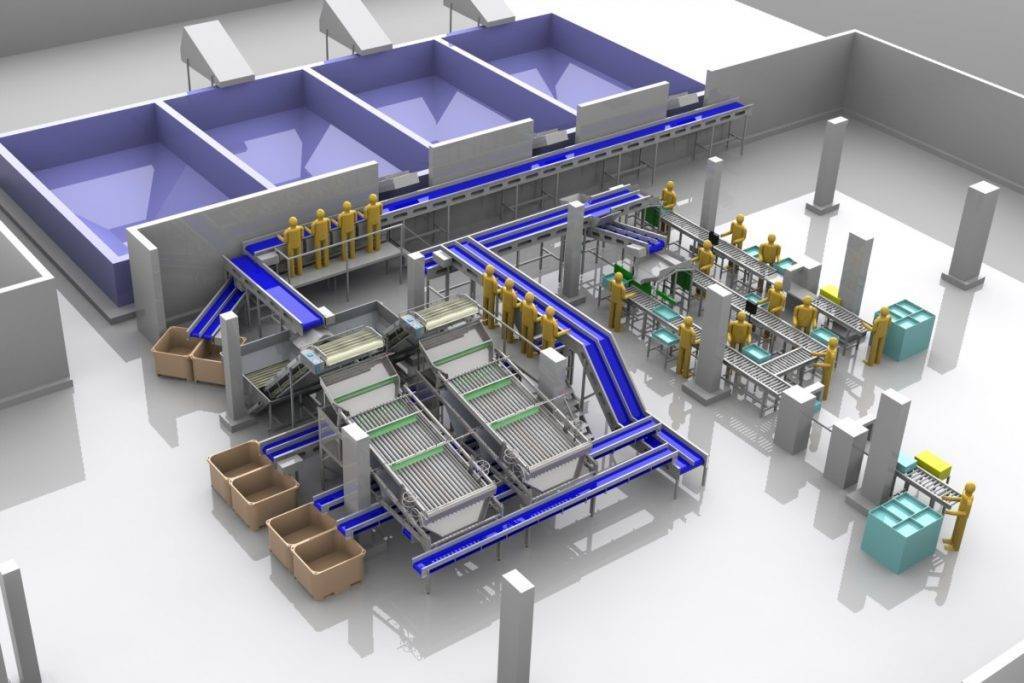

When you begin sourcing various raw foods like fish, meat, fruit, or vegetables for your manufacturing process, you’ll encounter three main types of production technologies in the industry: custom production lines, turnkey solutions, and customized turnkey solutions. Each type offers different advantages depending on your business needs. Understanding these differences is crucial for deciding which solution best fits your operations. Let’s take a closer look at each option to clarify their unique features and help you make an informed decision.

Custom production lines

If you’re a fish processing or food packing company that wants something that is created from the ground up and fitted exclusively for your organization, it would be best to buy a production line that’s custom-made.

When you buy a production line in this way, it’s important to understand that you might need to source individual pieces of equipment from various suppliers and integrate them into a single factory line. After thorough customization, this will streamline and enhance the flexibility of your system operations.

What are the benefits and disadvantages of these production lines?

If you decide to go with the custom production line solution, you can be sure that:

- most, if not all, of your company’s needs, will be covered because this type of production line is so tailored for individual organizations

- it can be designed to work with your already existing business procedures

- you’ll be able to set it up step by step in different stages

- you can install any extra equipment afterward if needed, so as your production volume increases, you can alter your production line to better support your operations

- Allowing for practical enhancements over time is a big advantage, as your company’s long-term goals are kept in mind when you buy production lines of this style

But you also have to keep in mind these disadvantages that come with custom production lines:

they need more resources for their development than some other solutions

if you’ll need some enhancements in the future, they’ll have to be custom-tailored as well

because they’re quite a unique setup, they may come with some higher risks

they might take a long time to install and set up

When should you choose to buy a production line like this over other options?

A custom production line will work the best for fish processing or food packing companies if there’s no way to find already existing turnkey solutions exactly for your business’s needs and goals. Alternatively, maybe you just need to buy a production line that’s newer and more technologically enhanced than your current line.

Keep in mind that this solution will suit your company if you have appropriate in-house tech support that will be able to take care of the line and your company has the budget and time to install and maintain the system.

Turnkey solution

As the name itself requests, turnkey solutions are so complete that they only need to be turned on with a key to get their job done. Based on your company’s work field, you may already have a variety of easily available turnkey solutions to pick from.

To make it even easier for you, many production line manufacturers that sell different turnkey solutions will frequently have professionals on hand to assist you with everything from implementation to maintenance.

What are the turnkey solution benefits and downsides?

If you decide to buy production lines with a turnkey solution for your manufacturing business, you can be sure that:

- your company will be exposed to fewer risks because, unlike custom production lines, turnkey solutions have been already tested

- this is the best choice for small and medium businesses because it costs less money, coming with many features by default

- you’ll have to communicate with only one company that also has readily available support with solutions on hand

- the manufacturer you buy your turnkey solution from can provide you with any future enhancements if needed

However, just like any other technology, turnkey solutions, too, have some disadvantages and downsides you have to keep in mind. For example:

- they are not so flexible, meaning that, unlike custom production lines, they are quite hard to customize

- you’ll probably need to modify any existing procedures to the new system

- you might get some maintenance and per-seat costs

- In some cases, opting to buy production lines like these can turn out more expensive than expected, if you decide not to go with some pre-packaged options

When should you buy a production line like this over other options?

Turnkey solutions will be the best for your manufacturing business if you’re looking to buy a production line that already has many features and is well-integrated from the ground up.

This solution is great if your company doesn’t have professional technicians and if buying each piece of equipment separately to build a manufacturing line from the beginning isn’t feasible due to limited time, money, or resources.

Choosing a complete, ready-to-install production line makes setting up easier and cuts down on upfront costs. It also lets you concentrate on making your operations run smoothly instead of dealing with the difficulties of putting different pieces of equipment together.

Customized turnkey solutions – best of both worlds?

If you’re looking for a ready-made food production line but want to customize some parts of it, customized turnkey solutions might be the way for you! When you buy production lines like this one, it means you can have an off-the-shelf solution that you can adapt with more features to meet your business goals to the maximum.

What benefits and disadvantages can you expect from choosing this solution?

If you decide to buy a production line like this one, you can be sure that:

- you’ll be able to get the necessary changes to already existing solutions pretty fast

- this solution may provide some flexibility with your old or existing, as well as future systems

- your business will get more competitive advantages, thanks to the unique customizations that will work in favor of your distinctive company

- the vendor you buy your production line from will still be able to give you direct support if needed.

But, like always when you buy production lines, you have to keep in mind some disadvantages that come with custom turnkey solutions. Such as:

- you have to be very mindful about the customization levels you want for your company – if you over-tweak your manufacturing line, you may wind up paying the same amount as if you constructed your system from the ground up

- this one depends on the manufacturing line, but you may not always be able to add some functionalities and features through modification

- you have to be prepared that by choosing the wrong off-the-shelf option from the start, the advantages of your modification may be minimized.

When to buy a production line like this one over other solutions?

This type of solution for your manufacturing line might be optimal if you have discovered an excellent turnkey solution that effectively meets most of your company’s needs. However, you might also find that there are areas where functionality could be improved. Further enhancements could ensure that the system not only meets but exceeds your operational requirements.

Keep in mind that when you buy production lines like this, it can be useful to find a base solution that covers at least 80% of your company’s main needs so that you can avoid overpaying for unnecessary customizations while also avoiding potential system performance difficulties.

Buy a production line that truly fits your business: expert advice from PERUZA

When you’re ready to take that all-important step in expanding your food processing business by selecting the best manufacturing solution, we recommend consulting with experts before you buy a production line. Seeking professional guidance can help ensure that the investment aligns with your business goals and operational needs, so you can have clarity and confidence in your decision.

Industry professionals, such as PERUZA engineers, will first seek to comprehend all the nuances of your business, guiding you toward the most suitable solution that fully addresses your needs. These experts are proficient in manufacturing technologies and can provide invaluable advice on specific equipment or features that might have been overlooked. Their insights can ensure that the production line you choose enhances your operational efficiency and productivity.