When we talk about canned food, the first thing that comes to mind is that it has a longer shelf life and is easy to preserve. Having a stock of canned goods at home is a lifesaver and an easy way to make dinner. You’ll probably find some old soup cans or green bean cans you purchased from who knows when if you dig far enough toward the back of your pantry.

But how long does canned food really last? There are many factors that can impact the shelf life of canned goods like – corrosion and rust, high temperatures, and other container problems. Just be careful to avoid purchasing bulging, rusted, leaky, or dented cans, and keep your canned foods in a cool, dry location instead of somewhere that may be exposed to extreme heat or cold, such as beneath a sink, above or next to a stove, in a wet garage, or in a basement.

In this blog post, we will look into the shelf life of canned goods and compare two types of autoclaves.

How long does canned food last?

It is advised to eat various canned products by a specified date for the greatest quality because, with time, many canned foods will experience flavor and texture changes and may eventually lose their nutritional value. It follows that the “use-by” or “best before” dates that are frequently put on cans are for quality, not safety. Although canned foods that exceed their “best-before” dates may not taste as nice, as long as they are still in excellent condition, there is no serious health risk associated with eating canned foods.

After opening canned foods, it goes without saying that you should put any leftovers and unused portions in the refrigerator. For the greatest quality and taste preservation, keep them in glass or plastic storage containers, avoid keeping them in cans. And the reason is that tin and iron can contaminate food, alter the flavor, and occasionally have a harmful impact on health. If the product is highly acidic, such as fruits and tomatoes, keeping open cans in the refrigerator is extremely risky.

So, let’s take a look at how long a different type of product will last canned:

Fish, meat and low-acid canned foods include stews, spaghetti, soups (apart from tomato soup), meat, and poultry in cans, as well as vegetables including potatoes, corn, carrots, spinach, beans, beets, peas, and pumpkin. Also canned fish like tuna and canned meat. After being canned, these foods retain their freshness for 2 to 5 years on the shelf. If you store them in the refrigerator after opening, they retain their freshness for 3 to 4 days.

High acid canned goods – juices, tomatoes, fruit products (including grapefruit, pineapple, apples, peaches, pears, plums, and all berries), pickles, sauerkraut, and any item prepared with vinegar-based sauces or dressings. These goods have a shelf life of 12 to 18 months, but once opened, they only remain fresh in the fridge for 5 to 7 days, but remember to remove them from the original can to a plastic or glass container.

But what is the secret of so long shelf life? Because all the microorganisms are eliminated during the canning process, canned food isn’t loaded with chemicals and preservatives. Cans that have been sealed in this way can stay fresh for many years. And one of the crucial parts sterilization of cans with hot water or air. So, in this part, the autoclaves step in.

Source: Steriflow

What is an autoclave? And which one is better?

Autoclaves are hermetic containers designed to endure high temperatures and pressures that offer a thermal treatment for a while at a high temperature. It is frequently used in the production of food to sterilize glass and metal containers. There are different kinds of autoclaves, but let’s look at 2 of the most popular ones in the food processing industry:

Autoclave using water

A retort also called an autoclave or sterilizer is a pressure vessel used in the food processing business to “commercially sterilize” food with steam and air after it has been placed into its container and the container has been hermetically sealed. A production retort is a sort of autoclave that sterilizes food using water spray and steam under pressure after packing and before it is shipped to market in order to give it a longer shelf life. Retorts are industrial-sized devices that can sterilize huge numbers of containers in a variety of sizes, shapes, and materials. The sterilization temperature and duration are predetermined and automatically managed by the computer. The most common temperature for autoclave sterilization is 121°C, but many cycles can reach higher temperatures, such as 132°C and 134°C. The water spray effectively transmits heat to the food containers to break down the bacterial and spore protein structures. This sterilizing procedure extends the shelf life of the food goods. The main benefit of an autoclave is – it washes away bacteria, literally. Water spray flows through the smallest schisms and gaps, maintaining a high-quality result.

Hot air retorts

In order to generate an overpressure in the retort, a mixture of flexible pressure steam and the air is added. This is called steam air type. Similar to water immersion and water spray, it is an over-pressure procedure, except instead of the water, the product is subjected to the effects of overpressure air. The thermal processing of a wide range of containers, including glass, metal cans, rigid plastic, and flexible pouches, is made possible by air overpressure. The main benefit of steam and air technology is that it is as efficient as steam and water, but it is more cost-effective by using less energy. The amount of energy needed to heat up air is far less than it is to heat up water. As a result, the cost is decreased and the heat treatment cycle lasts less time and is more consistent.

But which one is better? And again, there is no simple answer to this. It depends on the product and packaging type. But, if we take fish processing, for example, specialists tend more toward the water type. And why? Because traditionally fish canning factories have open-type baskets, which are designed for water spray. The autoclaves of direct steam use more closed-type baskets.. But, keep in mind, if you choose hot air retort it will be a more cost-effective choice.

Source: PERUZA

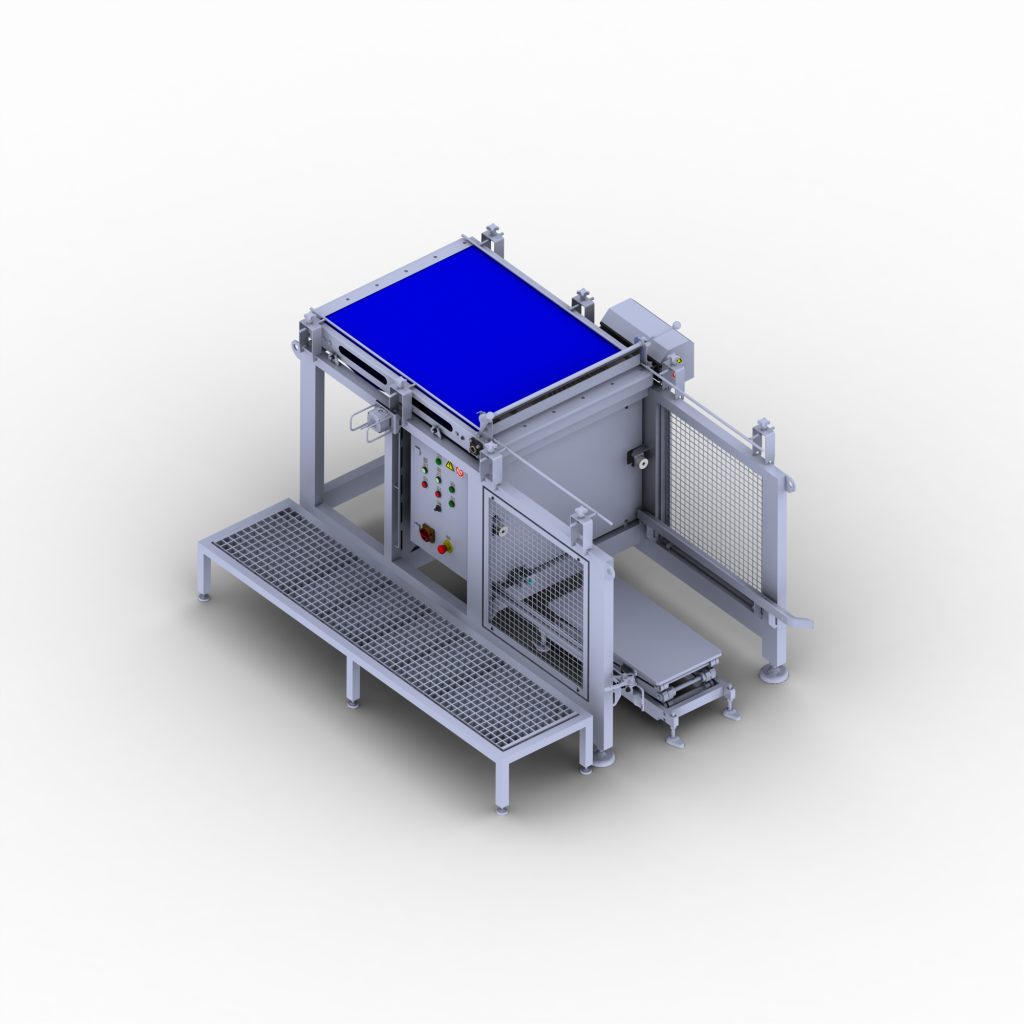

PERUZA’S Autoclave basket loader and autoclave basket unloader

PERUZA offers two amazing solutions for those who have chosen to work with autoclaves.

The autoclave basket loader and the basket unloader are made to load and unload specified kinds of autoclave or retort baskets. Cans are stacked in rows and layers in the basket, with a plastic interlayer cushion separating each pair of layers. The machine comes in manual, semi-automatic, and automatic (only for unloader) versions. The main benefits? The autoclave basket loading and unloading process is quicker and the design and operation are more ergonomic, secure, and clean.

How do these solutions work? It is necessary to insert the autoclave basket and position it above the lifting platform. Once it has been properly installed, the operator uses the control unit to raise the can layer using a hydraulic lift so that the top layer of cans is evenly spaced from the conveyor surface. This is done automatically for our automatic-type basket unloader.

Moving cans from layer to conveyor surface can be done with manual work or automatically with a pneumatic pusher. When a layer is empty, the operator must remove the separating sheet before raising the following layer to the correct height. Again this is done automatically for the machine’s upgraded version.

Final thoughts

No doubt canned foods are safe and accessible ways to store food for a longer period and keep them within arm’s reach. And the manufacturer’s task is to produce canned foods that not only taste good but also have a longer shelf life, right? And autoclaves are a crucial part of that task. But autoclave basket loaders and unloaders can ease the process and make it faster and more efficient.

As robotics, automation, and machinery develop, you must look into the best possible solutions now. If you’re interested in learning more about how PERUZA can help you get the best results with your food processing, feel free to get in touch at info@peruza.com, and we’ll be happy to discuss the possibilities of us creating something great for your fish processing business!